As the coronavirus (COVID-19) pandemic continues, health-care professionals continue to face new challenges. In a time of need, some health-care professionals have suggested using continuous positive airway pressure (CPAP) machines in lieu of ventilators to treat seriously ill COVID-19 patients. However, one of the biggest concerns with placing an infected patient on this machine is the aerosolization of viral particles, which can infect others.

A team of Hopkins undergraduates sought to address this problem when they returned home in March at the beginning of the national health crisis.

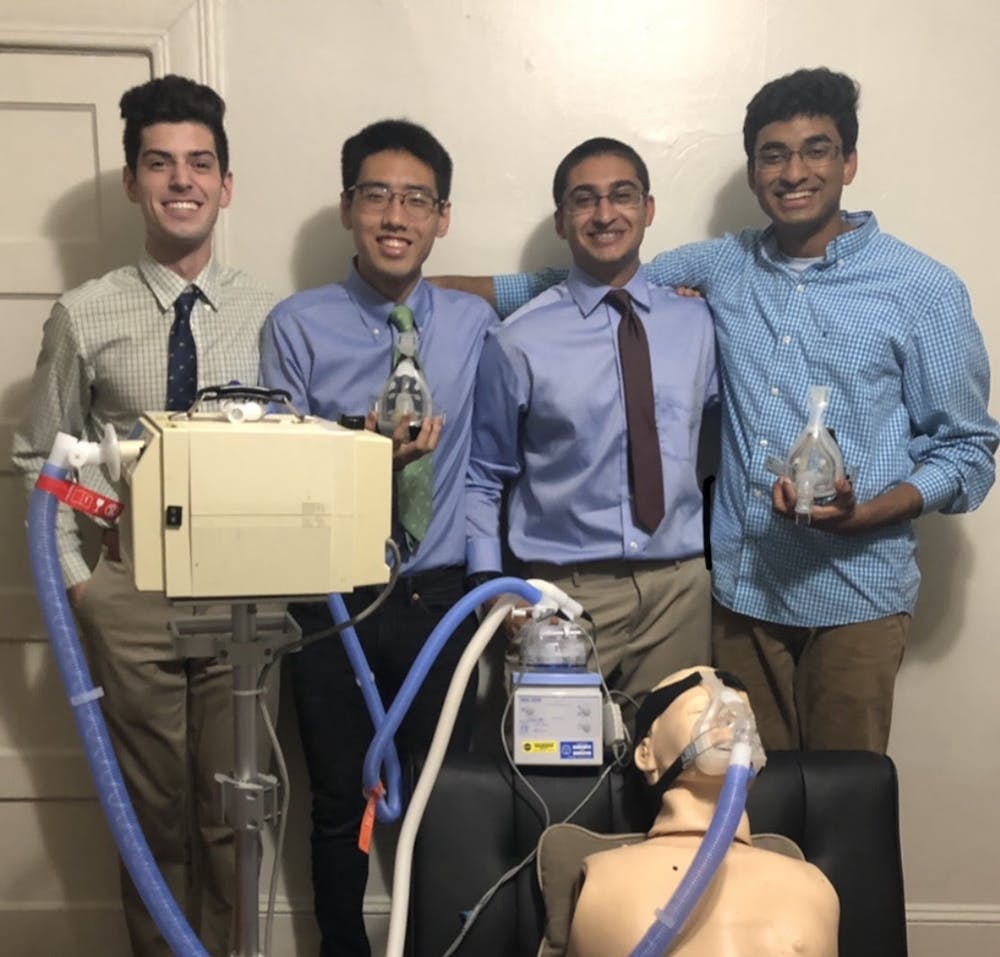

Min Jae Kim, a junior Biomedical Engineering major, put together a team of undergraduates to create a solution for the rapid spread of the virus using CPAP machines.

Kim was joined by juniors Adam Kenet, Ankur Govil and Joshua Ni, who are all Biomedical Engineering majors, as well as Varahunan Mathiyalakan, who is majoring in Chemical and Biomolecular Engineering.

First, the team conducted preliminary background research for two months regarding COVID-19 and mechanical ventilation. They then reached out to medical professionals at Hopkins, such as Amir Manbachi, an assistant professor of neurosurgery and biomedical engineering, for further advice.

For funding, they applied to opportunities offered by Agara Bio, a student-led community biology lab at Hopkins. Since June, the team has been working on developing a device that can minimize the spread of aerosolized viral particles from an infected patient on a CPAP machine.

“There was one hypothesis that we had that later proved wrong,” Mathiyalakan explained in an interview with The News-Letter. “We initially thought that the main source of leaks was due to [viral particles] escaping through material. Rather, there’s a gap, so the mask isn’t conforming directly to the patient’s face, and that’s where the aerosolized particles are escaping.”

The team then combined their initial research and engineering knowledge to design a device to close the gap. They turned to memory foam because it is a pliable, widely accessible material. They created a memory foam attachment for the CPAP mask. The purpose of this attachment is to close the gap between the mask and the patient’s face so that there is no space for the aerosolized viral particles to leak.

The team has conducted efficacy tests of their prototype by using LED lights to visualize the viral particles released from a patient’s respiratory tract. This aerosol was simulated with the use of a CPR dummy.

“We can then test the efficacy of the prototype by applying a CPAP mask with padded-foam on the dummy, and see if we can visualize the release of aerosol particles via these lights,” Kim explained in an email to The News-Letter.

The team did not comment on the results of these efficacy tests. However, Kim mentioned the prototype is ready for clinical testing and is awaiting an Institutional Review Board (IRB) approval.

The IRB requires a sub-approval from the Food and Drug Administration (FDA) for clinical efficiency testing of new devices. The FDA provides an exemption for devices that make a minor change to pre-existing FDA devices utilized for their pre-approved purposes. The team is not yet sure if they qualify for this exemption, but they are working towards submitting their first draft of their IRB. They hope for the application to be approved by October.

The team is currently working on designing a new prototype.

“We realized that our early stage, just memory foam [prototype] probably is not going to work,” Mathiyalakan said in an interview with The News-Letter. “Since then, we’ve refined our concept a little bit. We are still in the design phase, but we’re talking with people from the Center for Bioengineering Design, and we’re thinking of a three-pronged approach.”

The three features include a material that conforms to the face, an impermeable material and an adhesive to stick the memory foam attachment onto the mask. The need for an impermeable material is to minimize the amount of aerosol leakage. Although the memory foam prototype conforms to the face to reduce gaps, aerosol can still leak through the foam.

“We would implement an impermeable yet flexible material resembling film to provide an additional mechanism to fully prevent the aerosol leakage for future prototypes,” Kim wrote in an email to The News-Letter.

Others have also attempted to address this issue. A pair of Harvard and Yale professors designed a circuit that is able to filter air breathed in and out by patients on positive airway pressure machines. The Hopkins team believes that their design is more useful because of its simplicity.

“A memory foam add-on device would be easier for clinicians to adapt into their workflow,” Kenet said in an interview with The News-Letter. “We would just give them the memory foam padding with some adhesive that they can peel off, and they would just be able to attach it onto their CPAP masks directly.”

To address the potential spread of viral particles from the exhalation port, the team suggested the use of a filter, but no further information was provided regarding this design.

The group is hopeful for their device’s impact in the medical community.

“It could potentially reach beyond just COVID,” Govil said in an interview with The News-Letter. “This could potentially go beyond just the respiratory issues of COVID but other respiratory diseases as well.”

Errata: This article originally stated the students received funding from the SNF Agora Institute. They received funding from Agara Bio. The News-Letter regrets this error.