The Department of Mechanical Engineering hosted its 25th Annual James F. Bell Memorial Lecture in Continuum Mechanics on Oct. 31. This year, professor Tresa M. Pollock from the Materials Department at the University of California, Santa Barbara, delivered a talk regarding the implications of the new TriBeam technology on characterizing alloys, entitled “At the Crossroads of Additive Manufacturing, Analytics and Advanced Materials.”

Professor James F. Bell, who the lecture commemorates, joined Hopkins as a faculty and researcher in 1945. At Hopkins, he conducted research in nonlinear mechanics and dynamic plasticity in metals and became a renowned expert in the fields of solid mechanics and physical pumps.

While he was in the process of developing a mechanical pump for cardiac surgery with the Hopkins Medical School, Bell was appointed the first director in a doctoral program of the department now known as Biomedical Engineering. As recognition for his tenure at Hopkins, Bell was awarded the President’s Medal in 1995.

To continue Bell’s legacy, this annual lecture seeks to promote discussions on modeling and understanding materials, and has showcased a line of speakers distinguished in the field of material mechanics.

“We try to come to this talk every year,” PhD student George Weber said in an interview with The News-Letter. “Usually there are very high caliber professors giving quality talks on continuum mechanics.”

Professor Pollock’s talk about TriBeam is the latest in the series.

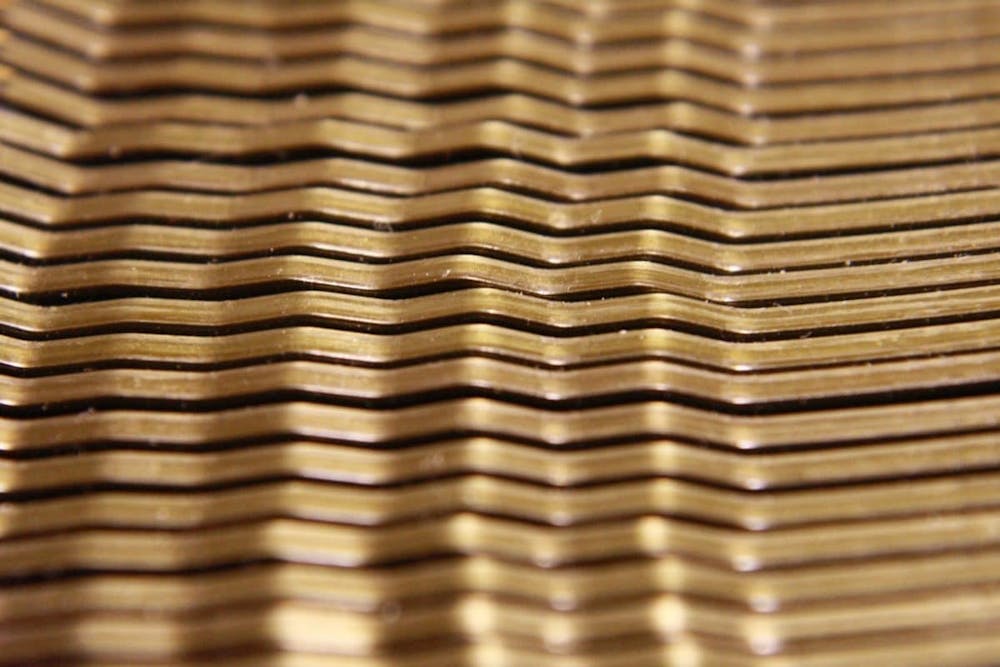

The TriBeam technology facilitates modeling by providing three-dimensional, high fidelity information about the characteristics of the studied sample. It involves pulsing a material sample with three distinct beams of ions, electrons and femtosecond lasers, producing a high resolution image with virtually no thermal damage to the surrounding area.

Pollock opened her talk by first acknowledging the potential for developments and breakthroughs in the field of advanced materials.

“If you take a look at the periodic table, there are nearly limitless combinations of molecules and architecture that one can come up with to get new materials,” she said.

According to Pollock, many fields that are capturing the headlines today, such as aerospace engineering, demand materials tailored to their needs.

The current most sustainable approach to developing those new materials is through 3D printing. Yet, Pollock pointed out that this is a complex process, in which scientists need to address three-dimensional problems. In addition to difficulties with the production of materials, scientists are concerned with predicting its properties to determine its usefulness. Sensors used to study those aspects can generate large amounts of data, which slows down the progression the experimentation, computation and data analysis processes.

“This has been one of the frustrations of the materials discipline: how do we better integrate those tools to discover and predict materials with some bounds of confidence,” Pollock said.

According to Pollock, the TriBeam approach will address this issue by bringing about the automation of data acquisition, reconstruction, analysis and sharing.

The three distinct beams that comprise TriBeam are capable of rapidly generating data about the properties of the sample layer-by-layer, with almost no damage. It can be employed to study a wide range of materials, requiring only very small sample sizes. Furthermore, Tribeam is also coupled with data reconstruction software and data sharing platforms, completing the aforementioned process of experimentation, computing and analysis all at once.

Pollock concluded her talk by reaffirming that efficient and accurate data analysis is crucial to designing materials, and that TriBeam technology is a useful tool for researchers to carry out those quantitative assessments.