Often regarded as being in the realm of science fiction, due to recent advances in textile fabrication wearable electronics are no longer a distant possibility.

Researchers at the Ohio State University have been able to incorporate circuits into fabrics with high precision, allowing for the manufacturing of fabrics that can gather and process information from the wearer. These advances are an improvement from the previously patented method that the team developed two years ago.

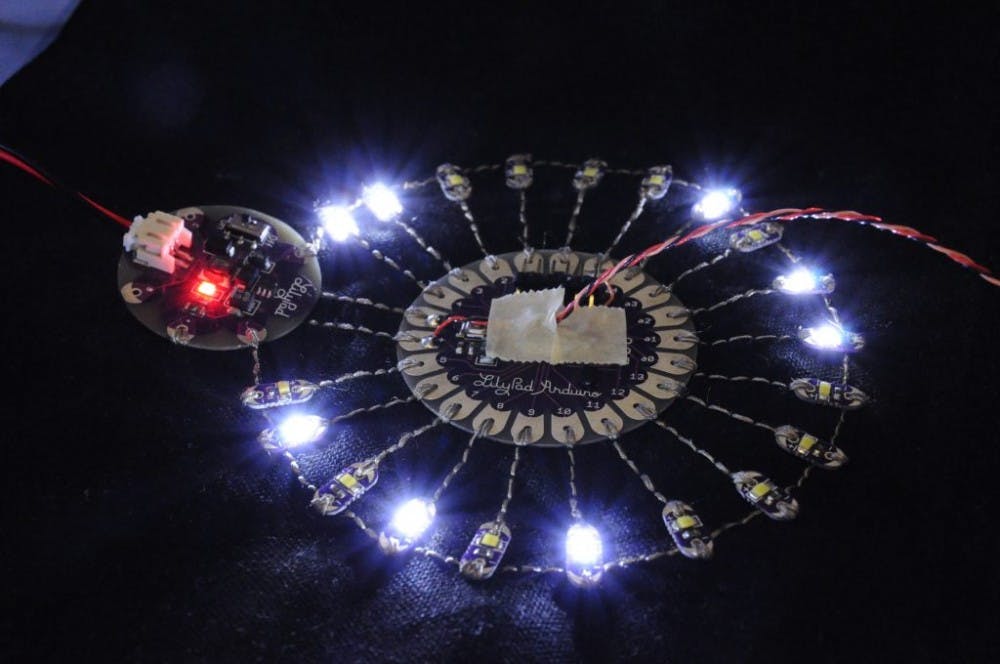

The process uses fabrics called e-textiles which are manufactured from thin composite wires. These wires are loaded onto a regular sewing machine and embroidered into patterns uploaded by the scientists. To create a functional textile, fabric patterns must be specifically designed to have functional electronic components such as antennas or circuits. For instance, an antenna that can transmit a broad range of frequencies has the pattern of interlocking circles where each circle transmits a different frequency. When operated together, these circles can transmit data over a broad range of frequencies, creating a broadband antenna.

A difficulty in creating these intricate designs is achieving the necessary precision. The different parts need to be embroidered into the fabric with a precision of 0.1 mm, especially when manufacturing sensors. The researchers discovered in previous attempts that achievable precision was limited by the size of the wire and its conductivity.

By using a thinner wire, the scientists can increase the precision of the sewing machine. The trade off is a reduced surface conductivity, which results in poorer sensor or antenna performance. Therefore in order to create workable electronic fabrics, scientists have to consider both precision and surface conductivity.

Older fabrication techniques utilize 0.5 mm thick silver-coated polymer threads for embroidery.

Recently the focus has been on using silver-plated copper threads that are 0.1 mm thick, which allows for better conductivity and precision.

The coated polymer threads are usually embroidered in two stacked layers to improve signal conductivity. On the other hand the coated copper wires have a high enough conductivity that the only one layer is needed for proper conduction. This characteristic offers the advantage of lowering the cost and the manufacturing time. A wearable antenna uses about 10 feet of copper thread, which costs about 30 cents and takes 15 minutes to create. A similar antenna made of coated polymer would cost more than seven dollars and half an hour of manufacturing time.

In addition to using copper threads, the new technique incorporates several designs found in microelectronics. Instead of designing antennas as circles, researchers created spiral antennas that are more efficient. The spiral antennas can experimentally transmit a range of frequencies from one to five GHz with almost perfect efficiency. These antennas can improve cellular and internet connection if embroidered in clothing.

Please note All comments are eligible for publication in The News-Letter.